Lithium-ion batteries are generally not recommended to be charged with standard chargers unless certain conditions are met. In some cases, although it is possible, most traditional chargers cannot meet the precise voltage and current requirements of lithium-ion batteries. This section discusses the reactions of lithium-ion batteries to various chargers, and why using dedicated lithium-ion battery chargers, such as those provided by Keheng, is often the best choice for maintaining battery health and performance.

Choosing the Appropriate Lithium-ion Battery Charger: Understanding the Charging Characteristic Differences between Lithium-ion and SLA Batteries

Understanding the charging absorption characteristics of lithium-ion and SLA batteries is crucial for choosing the appropriate lithium-ion battery charger. These batteries exhibit significantly different charging profiles. SLA batteries typically use three stages: constant current, constant voltage (or absorption phase), and float charging. Conversely, lithium-ion battery chargers only operate in two stages: constant current and constant voltage.

SLA Battery Charging Process

The initial stage for SLA batteries is the constant current stage, during which the battery receives the majority of its charge. For example, a 12V 20Ah SLA battery may take about 3-4 hours to reach about 80% of its total capacity. Once this level is reached, the process transitions to the constant voltage or absorption phase. This phase completes the final 20% of charging, which may last as long as the first stage, accounting for about 50% of the total charging time. The final stage, float charging, keeps the battery fully charged to prevent self-discharge. Although this helps extend the battery’s life, it also extends the total charging time.

Why Lithium-ion Batteries Charge Faster

Charging lithium-ion batteries is significantly simpler and faster. Using a lithium-ion battery charger, the first stage (constant current) charges the battery to 99% of its capacity. The remaining 1% is in the second stage, constant voltage, much shorter than the absorption phase of SLA batteries. This simplified process means that lithium-ion batteries can be charged three times faster than SLA batteries of the same capacity.

For example, a 12.8V 20Ah lithium-ion battery may reach almost full charge in about 2.5 hours, while an equivalent SLA battery may take over 6.5 hours. This fast-charging capability makes lithium-ion battery chargers an ideal choice for applications like golf carts, boat systems, and backup power solutions, among others.

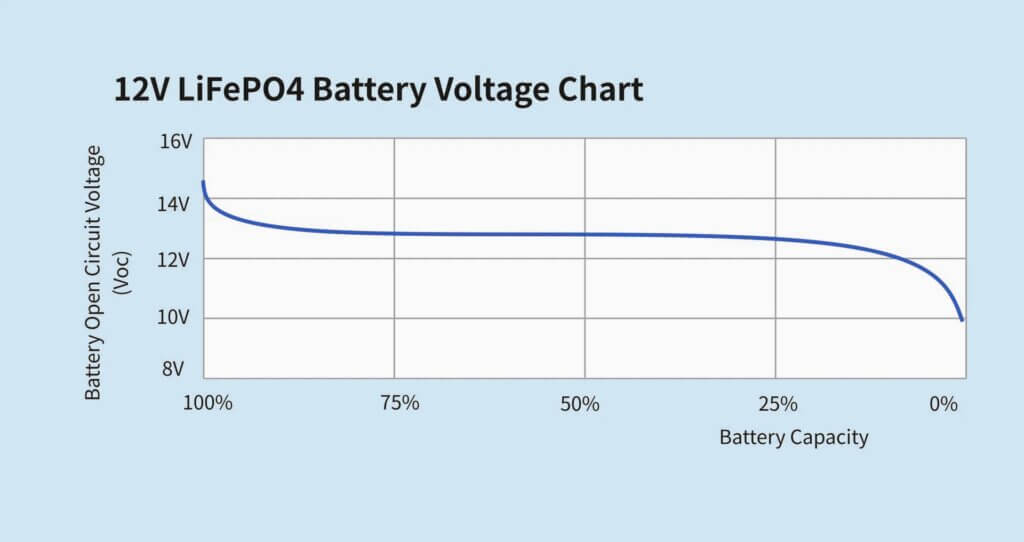

The Importance of Voltage Profiles

An important difference between SLA and lithium-ion batteries lies in their voltage profiles. A fully charged 12V SLA battery typically reaches about 12.7V, while a lithium-ion battery can reach as high as 13.4V upon full charge. This narrow voltage range is crucial for ensuring the optimal performance and longevity of lithium-ion batteries, highlighting the necessity of using chargers specifically designed for lithium technology, such as those provided by Keheng.

Charging lithium-ion batteries with standard sealed lead-acid (SLA) chargers presents challenges due to varying voltage requirements. Using SLA chargers can result in overcharging or undercharging of lithium-ion batteries. To prevent these issues, it is essential to use a universal lithium-ion battery charger specifically designed for the precise voltage needs of lithium-ion batteries.

The best option for charging lithium-ion batteries is to use a dedicated charger designed for lithium-ion batteries, which utilizes CC/CV (constant current/constant voltage) charging algorithms. This ensures safe and efficient charging. Unlike SLA chargers that may continuously trickle charge, lithium-ion battery chargers cease charging once the battery reaches full capacity, thereby preventing overcharging.

The Reaction of Lithium-Ion Batteries to SLA Charging Configuration

A common question is whether it is safe to charge lithium-ion batteries with SLA chargers. The brief answer is: yes, but with conditions. Understanding this requires examining how lithium-ion batteries absorb charge compared to SLA batteries, particularly when using chargers designed for different battery types.

The primary issue with charging lithium-ion batteries using SLA chargers is the discrepancy in charging curves. Most SLA chargers operate within a constant voltage range of 13.8V to 14.7V. If a lithium-ion battery is charged at around 13.8V, its lower internal resistance allows it to reach 95% of its total capacity during 90% of the charging time, allowing for faster energy absorption.

However, at higher voltages, around 14.6V—typical for AGM batteries—the lithium-ion battery can reach 99% of its capacity during 95% of the charging time. This means higher voltages result in more efficient charging, enabling the lithium-ion battery to reach full capacity quickly.

Increased Charging Time with SLA Charger

While it is technically possible to charge lithium-ion batteries with an SLA charger, the charging time will be longer than with a dedicated lithium-ion battery charger. For instance, a 20Ah lithium-ion battery may take approximately 2.5 hours to charge using a standard lithium-ion charger. In contrast, the same battery may take up to 5 hours to fully charge using an SLA charger. This is because the SLA charging configuration is not suitable for lithium-ion batteries, leading to lower energy absorption efficiency during the constant voltage phase.

Despite the longer charging time, lithium-ion batteries will charge faster than typical SLA batteries when charged with an SLA configuration. This is due to the inherent properties of lithium-ion batteries, which can absorb more energy during the bulk charging phase and reach a higher state of charge in a shorter time. Even with non-optimized chargers, the charging speed of lithium-ion batteries is usually superior to that of SLA batteries.

Potential Risks of Using SLA Chargers

Although it is technically feasible to charge lithium-ion batteries with an SLA charger, there are important considerations. Firstly, SLA chargers should not have desulfation mode or dead battery detection functionality. Desulfation mode uses high-voltage pulses to recover over-discharged SLA batteries, which can damage lithium-ion batteries and even cause their BMS to shut down. Similarly, dead battery detection mode may mistakenly identify lithium-ion batteries in protective mode as dead, thus preventing the start of charging.

Additionally, the charging voltage of lithium-ion batteries is more sensitive than that of SLA batteries. Using a charger with an output voltage outside the acceptable range will lead to damage to battery cells, resulting in reduced lifespan or permanent damage. This is why it is recommended to use a dedicated lithium-ion battery charger or a universal lithium-ion battery charger designed for these specific requirements.

The Optimal Charging Method for Lithium-ion Batteries

Adhering to specific voltage requirements is crucial for achieving optimal results when charging lithium-ion batteries. Charging efficiency can vary significantly across different voltage ranges. For instance, when using a charger set to the lower end of the voltage range (13.8V), lithium-ion batteries can rapidly reach 95% State of Charge (SOC), typically faster than lead-acid batteries, which can only reach 80% SOC within the same timeframe. Conversely, at the higher end (14.6V), which is the typical charging voltage for Absorbed Glass Mat (AGM) batteries, lithium-ion batteries can reach 100% SOC even more quickly, further demonstrating their superior charging capability compared to lead-acid batteries.

Although using a lead-acid battery charger is not the ideal choice, it can serve as a temporary solution when no other options are available. However, to ensure optimal performance and prolong battery life, it is strongly advised to use a Kehong Tech lithium-ion battery charger that meets the specific charging requirements of lithium-ion batteries. This approach minimizes risks and guarantees optimal performance, making it a safer and more efficient long-term solution.

Potential Risks of Charging Lithium-ion Batteries with Lead-acid Battery Chargers

When using a lead-acid battery charger to charge lithium-ion batteries, potential damage is a concern. The impact largely depends on the charger’s specific features and the battery’s usage. While standard lead-acid battery chargers may not cause immediate harm, several key factors must be considered to avoid long-term damage.

Understanding the Risks

The primary concern when using a lead-acid battery charger to charge lithium-ion batteries is the charger’s specific charging modes, such as desulfation or float charging. The desulfation mode, which is intended to recover over-discharged lead-acid batteries by sending high-voltage pulses, can cause particular damage to lithium-ion batteries. These high-voltage pulses can cause the battery management system (BMS) to shut down or, in severe cases, damage the battery’s internal cells.

Similarly, if the lead-acid battery charger includes a float charging mode, this may also pose a risk to lithium-ion batteries. This mode continues to apply a small current after the battery is fully charged, which is unnecessary for lithium-ion batteries. Due to their low self-discharge rate, lithium-ion batteries do not need to be maintained at 100% SOC for an extended period. Long-term exposure to float charging can reduce the battery’s overall lifespan and may even cause overheating.

Limited Charging Capacity of Lead-acid Battery Chargers

A major drawback of using a lead-acid battery charger is its inability to fully charge a lithium-ion battery. For example, a 20Ah lithium-ion battery may only reach 90-95% of its total capacity when charged using a standard lead-acid battery charger. This limitation is due to the slight difference in the working voltage range of lead-acid battery chargers compared to dedicated lithium-ion battery chargers. Therefore, this voltage difference prevents the lithium-ion battery from reaching full charge, limiting the battery’s available capacity.

For applications with high power demands, this can result in decreased performance or a shorter runtime. However, in low-demand scenarios, this difference may not be as noticeable. If maximizing battery capacity is the main objective, it is strongly recommended to choose a dedicated Kehong Tech lithium-ion battery charger.

Considerations for Daily Use and Long-term Storage

Another important factor to consider is whether the lithium-ion battery will be used for daily use or left connected to the charger for an extended period. In high-cycling applications, where batteries are frequently charged and discharged, even without desulfation or float charging modes, lead-acid battery chargers may not cause immediate damage. In such cases, the charger may not be connected for an extended period to trigger harmful effects.

However, if it is expected that the battery will be left connected to the charger for a long time, it is recommended to disconnect it after the battery is fully charged. Leaving a lithium-ion battery connected to a lead-acid battery charger for an extended period may cause unnecessary wear and potential damage.

Charging Li-ion batteries with an SLA charger during storage may inadvertently lead to floating charge, which may have an adverse effect on battery health. Li-ion batteries are best stored at about 50% charge instead of fully charged, so the battery should be disconnected when not in use.

Best Practices for Using SLA Chargers

If you must use an SLA charger to charge your Li-ion battery, please follow the following best practices to minimize potential risks:

- Avoid sulfation mode: If your SLA charger has a sulfation mode, do not use it. The high voltage pulses associated with this mode may damage the Li-ion battery or trigger the battery management system (BMS) to shut down.

- Disconnect after charging: To avoid the battery staying in floating charge mode, always disconnect the Li-ion battery connection once the battery is fully charged.

- Monitor voltage: Regularly check the battery voltage during the charging process to ensure it remains within a safe range. If the voltage exceeds the recommended range, stop charging immediately.

- Replace with a dedicated Li-ion battery charger: For optimal performance and safety, replace with a Li-ion battery charger. Dedicated Li-ion battery chargers will use the appropriate charging profile to prevent potential damage caused by incompatible voltage settings.

Can SLA Chargers Be Used in High-Cycle Applications?

In high-cycle applications where batteries are frequently charged and discharged, using a standard SLA charger may not cause significant problems, provided the charger does not have functions like sulfation. This is because the charger’s connection time is insufficient to cause floating charge or overheating. However, be aware that the battery may not achieve its full capacity, potentially reducing the effective runtime between charges.

In the end, using a Li-ion battery charger is always the safest choice to enhance battery performance and lifespan. Although SLA chargers can be used temporarily, it is recommended to replace them with a dedicated Li-ion battery charger whenever possible.

Can Li-ion batteries be charged with power sources?

Simply put, yes. But special attention must be paid to voltage and current settings, as power sources lack built-in safety features for automatic current regulation during the charging phase. Therefore, careful monitoring is crucial to prevent overcharging or damage to the battery cells.

How to Safely Use Power Sources for Charging

To safely charge Li-ion batteries, it is important to follow the following key steps:

- Set the correct voltage limit: Ensure the output voltage is set according to the specific type of Li-ion battery. For standard lithium-ion batteries, the voltage should be set to 4.20V per battery. For lithium iron phosphate (LiFePO4) batteries, the voltage limit is 3.65V per battery. If you are using a different type of Li-ion battery, verify the manufacturer’s recommended voltage limits before proceeding. Exceeding the safe voltage range can cause overheating or permanent battery damage.

- Set the current limit to 1C: The charging current should be limited to a maximum of 1C. For example, if you are charging a 2000mAh battery, the current should not exceed 2A. Setting the current too high generates too much heat and may damage the battery.

- Closely monitor the charging process: When using power sources to charge Li-ion batteries, monitoring the safety and efficiency of voltage and current throughout the charging process is crucial.

Battery Charging Process Overview

The process of charging a lithium-ion battery starts with the drawing of the maximum current from the battery. As the voltage approaches the set point—such as 4.20V per cell for standard lithium-ion batteries—the current begins to decrease. This stage is known as the constant voltage phase, where the current gradually diminishes until the battery is fully charged.

Stop Charging When Current Drops to 3% of Initial Value

Unlike commercial lithium-ion battery chargers, the power supply does not automatically stop charging after the battery is fully charged. To prevent overcharging, it is crucial to discontinue charging when the current falls to approximately 3% of the initial charging current. For instance, if the initial current is set to 2A, charging should be stopped when the current is below 0.06A.

Using Power Supply and Dedicated Lithium-ion Battery Chargers

While power supplies can be used to charge lithium-ion batteries, they lack the basic safety features found in dedicated lithium-ion battery chargers. Commercial chargers are specifically designed to accommodate the unique characteristics of lithium-ion batteries, such as maintaining precise charging voltage and automatically shutting off when the battery is fully charged. Relying on power supplies requires manual supervision, which increases the risk of human error.

In addition, commercial lithium-ion battery chargers reduce the current during the constant voltage phase to minimize unnecessary stress on the battery. In contrast, laboratory power supplies will continue to provide the set current, which can lead to overcharging if not carefully monitored. Therefore, it is always recommended to use a dedicated Keheng lithium-ion battery charger whenever possible.

Measuring Battery Charging with a Multimeter

To track the charging state of a lithium-ion battery, a multimeter can be used to measure voltage. For a single cell lithium-ion battery, the voltage should gradually rise from about 3.0V (discharged) to 4.20V (fully charged). If charging a series of multiple cells, simply multiply each cell’s voltage by the number of batteries in the battery pack. You can also use the power supply display to monitor charging current and voltage.

When the charging current approaches zero (for example, below 0.01A), the battery is considered fully charged. At this point, disconnect the battery immediately to prevent overcharging.

Precautions When Using Power Supplies

When charging lithium-ion batteries with a power supply, certain precautions must be taken to ensure safety:

– Ensure balance: If charging a series of multiple cells, ensure the battery pack is equipped with a battery management system (BMS) that includes balancing functionality. This helps maintain equal voltage for each battery and prevents overcharging of a single battery.

– Avoid overcharging: Do not connect the battery to the power supply after it is fully charged. Overcharging can cause overheating, expansion, and even pose safety hazards.

– Monitor temperature: Closely monitor the battery temperature during the charging process. If the battery becomes overheated, the charging process should be stopped immediately.

Final Recommendations

While laboratory power supplies can be used to charge lithium-ion batteries in certain situations, this is not the most reliable or safest method. The best way to charge lithium-ion batteries is to use a dedicated Keheng lithium-ion battery charger designed specifically to meet these batteries’ unique charging requirements. This ensures the battery is charged safely and efficiently, minimizing the risk of overcharging or damage.

Conclusion

In certain cases, using a power supply or lead-acid battery charger to charge a lithium-ion battery may be effective, but it requires caution and attention to detail. Always ensure the charger does not have desulfation or float charging mode, and closely monitor voltage and current. For the best results, the Keheng lithium-ion battery charger is the safest and most effective choice, ensuring the battery reaches full capacity while avoiding the risks of overcharging or damage.